Every day, countless products we use are shaped, cut, and crafted with laser machines. Whether it’s the metal frame of a building, a piece of custom furniture, or even parts for electronics, laser cutting plays a big role. In a fast-paced and competitive place like New York, industries need machines that work efficiently and deliver reliable results.

That’s why the gantry laser cutting machine in New York and other areas has become a popular choice. Alongside tools like the hand-held laser welding machine, these machines are helping businesses cut costs, speed up production, and improve quality.

Let’s dive into the main benefits of using gantry laser cutters and how they fit into New York’s industrial scene.

What Makes Gantry Laser Cutting Machines Different?

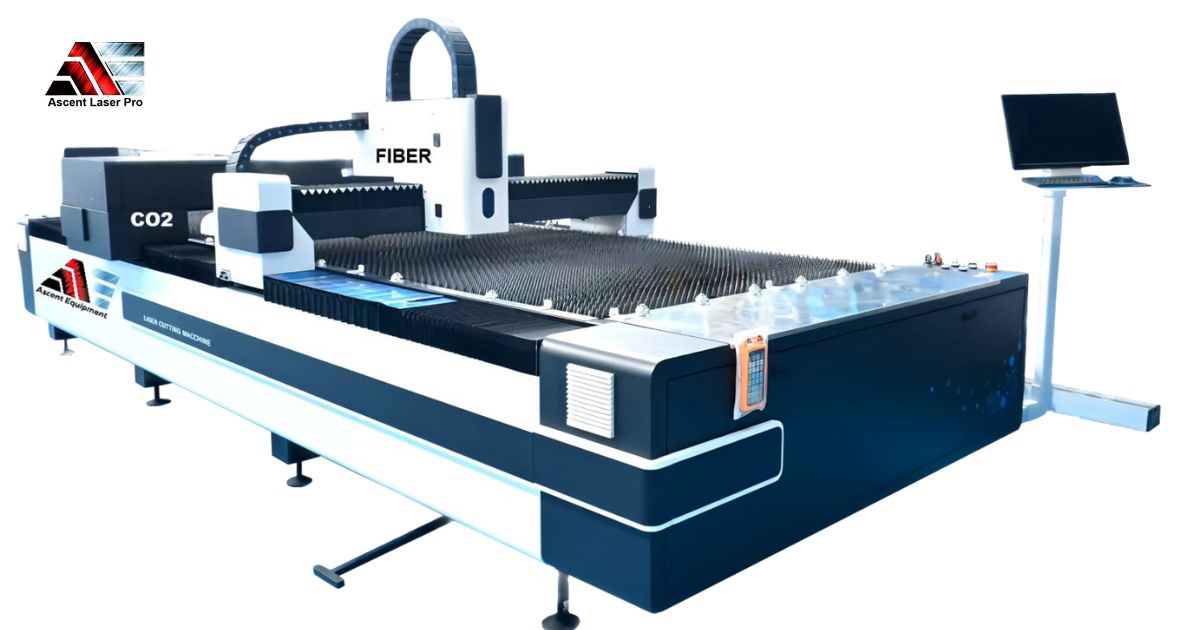

The term “gantry” refers to the structure that holds the laser head and allows it to move across a large workspace. Instead of moving the material, the laser head glides along this frame to cut or engrave. This design is great for handling big sheets of metal, wood, or other materials.

Many industries find gantry systems useful because they offer a large cutting area. That means no need to cut materials into smaller bits before working on them, which saves time and effort. Compared to smaller or desktop machines, gantry cutters can tackle much bigger projects in one go.

Big Working Area Meets High Efficiency

One of the biggest advantages of a gantry laser cutting machine in New York is its size. It can handle large sheets of metal or thick plates without hassle. This is essential in New York’s construction and manufacturing sectors where large steel sheets are common. The machine’s ability to hold and cut big materials in place reduces handling risks and improves safety.

The large workspace also means projects can move faster. Instead of stopping to reposition or reload material frequently, operators can cut multiple parts continuously. This steady workflow means less downtime and more output per shift.

Speed and Clean Cuts Mean Less Waste

Traditional cutting methods like saws or shears often leave rough edges or waste material. Laser cutting is a different story. It uses a focused beam of light to slice cleanly through metal or other materials. This results in smooth edges and less need for finishing work.

The speed at which gantry machines work is impressive. They cut quickly and precisely, reducing production times. That’s especially useful when deadlines are tight or when mass-producing parts.

Clean cuts also mean less wasted material. When edges are neat, there is less scrap, which saves money and reduces environmental impact.

Versatility in Materials and Shapes

Gantry laser cutters can work with a wide range of materials, including:

- Steel and aluminum sheets

- Wood and plywood

- Acrylic and plastics

- Fabrics and composites

This versatility means a single machine can serve many departments or projects. Whether it’s cutting metal panels for industrial equipment or delicate wood designs for furniture, gantry cutters deliver consistent results.

They also excel at complex shapes. The laser can cut curves, holes, and fine details that traditional tools struggle with. This makes gantry machines popular in industries like signage, automotive, and electronics.

Less Maintenance, More Production Time

Because laser cutting doesn’t rely on blades or physical contact, wear and tear is minimal. This means less downtime for repairs or replacements. Maintenance mostly involves cleaning lenses, mirrors, and checking alignment.

This ease of upkeep helps keep gantry laser cutters running longer with less interruption. In busy New York factories or workshops, this reliability is a big advantage.

Smart Features That Make Life Easier

Many modern gantry laser cutters, including those you can find at Ascent Laser Pro, come loaded with helpful features:

- Auto-Focus Systems: Automatically adjust the laser focus depending on material thickness. This saves time and ensures a proper cut every time.

- User-Friendly Software: Operators can upload designs directly and control cutting parameters easily through touchscreens or computers.

- Robust Construction: Solid frames reduce vibrations and improve cut quality, especially during long production runs.

- Energy-Efficient Operation: Advanced laser sources deliver power effectively, cutting energy costs without losing performance.

These features reduce human error and speed up training. For companies in New York, this means smoother production and better results.

How Gantry Laser Cutting Machines Fit Into New York’s Industry Mix

New York is home to many industries, each with its own needs. Gantry laser cutters fit well in many areas:

- Metal Fabrication: Cutting metal sheets into parts for buildings, vehicles, or machinery.

- Sign Making: Producing detailed letters, logos, and shapes for advertising and events.

- Furniture and Design: Cutting wood, acrylic, and other materials for stylish, custom pieces.

- Electronics: Making precise panels, enclosures, and circuit boards.

The machine’s ability to work on large materials and create complex cuts supports these varied uses. This makes it a versatile investment for companies with multiple product lines.

Gantry Laser Cutting and Hand Held Laser Welding Machines

You might also hear about the hand held laser welding machine in New York. These devices are great for welding or fixing metal parts in tight or hard-to-reach places. They are portable and flexible.

While hand held welders provide on-the-spot repair and joining solutions, gantry laser cutters are designed for large-scale, accurate cutting. They work well together in manufacturing or repair shops, but serve different purposes.

Getting the Most From Your Gantry Laser Cutter

To make the most of a gantry laser cutting machine, keep these tips in mind:

- Match the laser power to your materials and project needs.

- Clean optics regularly to maintain cutting quality.

- Use up-to-date software for smooth operation.

- Train operators well to reduce mistakes and increase efficiency.

Following these simple steps will help keep production steady and parts consistent.

What’s Ahead for Gantry Laser Cutting Technology?

The future of gantry laser cutting looks bright. Advances in automation, real-time monitoring, and faster lasers will continue to improve output and ease of use. New York businesses adopting these technologies can expect higher productivity and better product quality.

Ascent Laser Pro: Where Innovation Meets Reliability

In the fast-paced world of manufacturing and fabrication, having the right tools can make all the difference. Ascent Laser Pro delivers cutting-edge laser machines that blend power with ease of use, helping New York industries stay ahead of the curve.

From gantry laser cutting machines that handle the toughest jobs to versatile hand-held laser welding machines, their gear is built to keep your work smooth, efficient, and reliable. With Ascent Laser Pro, you’re not just getting equipment—you’re gaining a partner that fuels your success with technology designed for real-world results.

Ready to take your craft to the next level? Ascent Laser Pro is where quality meets performance.

Ascent Laser Pro offers advanced, FDA-certified laser solutions including fiber laser welders, CO2 cutters, and handheld welding systems. They provide expert guidance, installation, and training across industries, with a focus on safety and performance. With offices in Buffalo and Toronto, Ascent delivers high-quality, affordable laser equipment tailored to meet a variety of needs.